Customer brief

We discuss ideas with you on the phone, in a meeting, at our Packaging Creation Lounge, or during an Insight.

A carrot bursting with delicious treats

Make a lasting impression with luxury

Keep your products safe and secure

Every stage of the bespoke packaging process is personalised to your needs.

We discuss ideas with you on the phone, in a meeting, at our Packaging Creation Lounge, or during an Insight.

We establish scope of work and product needs such as single/multiple items, e-commerce, bulky, or fragile.

Our expertise and unique sources ensure you get the ideal materials for your product, operation, and brand.

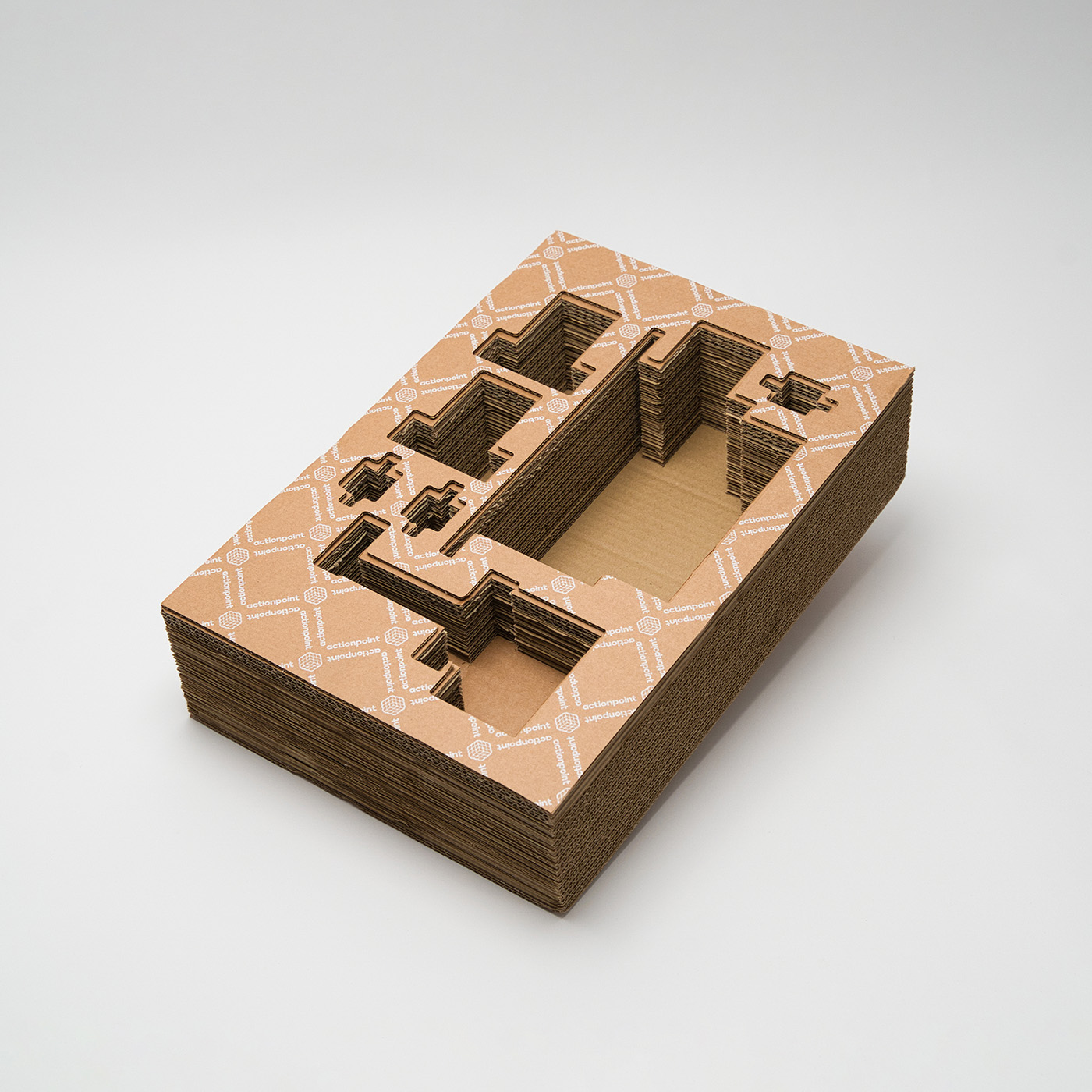

We create a sustainable packaging concept that meets your needs, solves any problems, and looks good.

Send us branding artwork such as a logo for us to add to the design, or we can create all the graphics in-house.

A physical sample is made within 24 hours, or same day if you are visiting the Packaging Creation Lounge.

Once the sample is approved, the order goes live, and the packaging is created in the required amounts.

We provide packaging for shipping boxes and pallets, as well as services like stockholding and assembly.

At Actionpoint, we have the skills and experience to help UK manufacturers from a wide range of industries.

Take a look at the types of businesses we currently support with personalised packaging solutions.

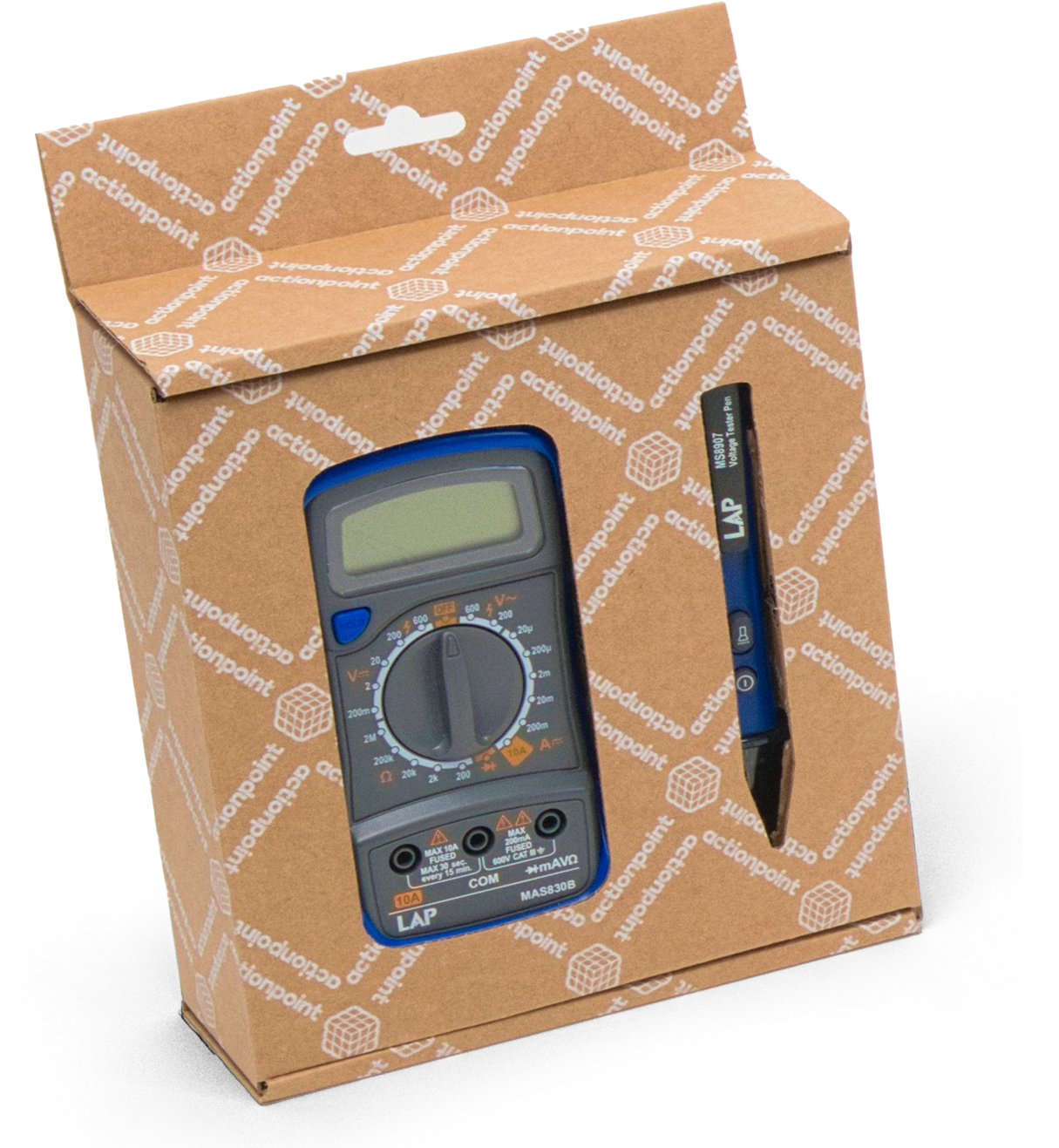

Electronic devices, components, and consumer electronics, which can be expensive, delicate, and vulnerable to electrostatic discharge (ESD).

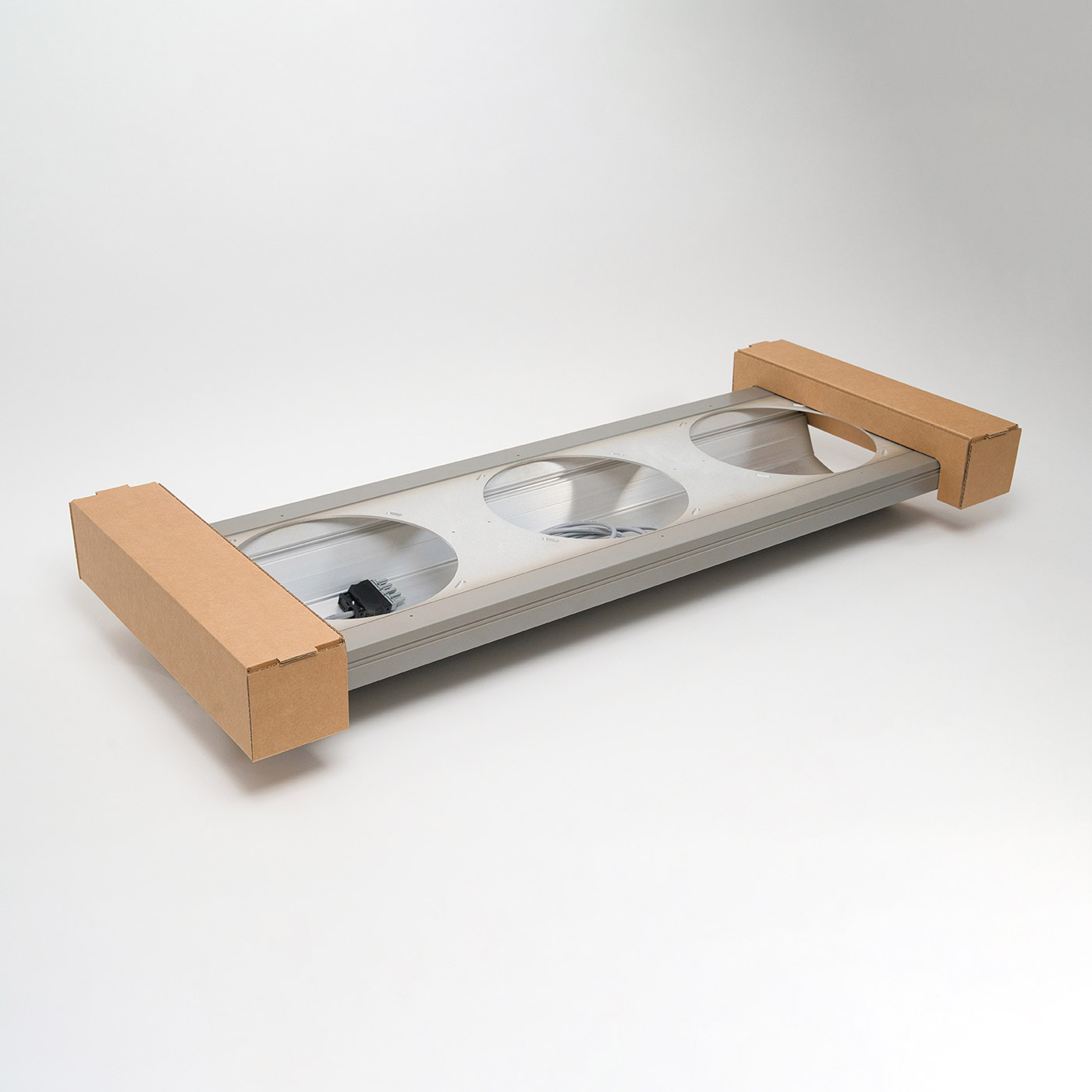

Businesses producing furniture such as seating, tables, and storage solutions, and manufacturers of industrial, commercial, or residential lighting.

Companies using plastic injection moulding to make household or business goods or parts, or makers of technical plastics for industrial use.

Medical and healthcare product manufacturers, including those relating to digital or robotic surgery, surgical training technology, and prosthetics.

Manufacturers of high-value mechanical products, electronics systems, vehicle interiors, and large components made of metal, plastic, or glass.

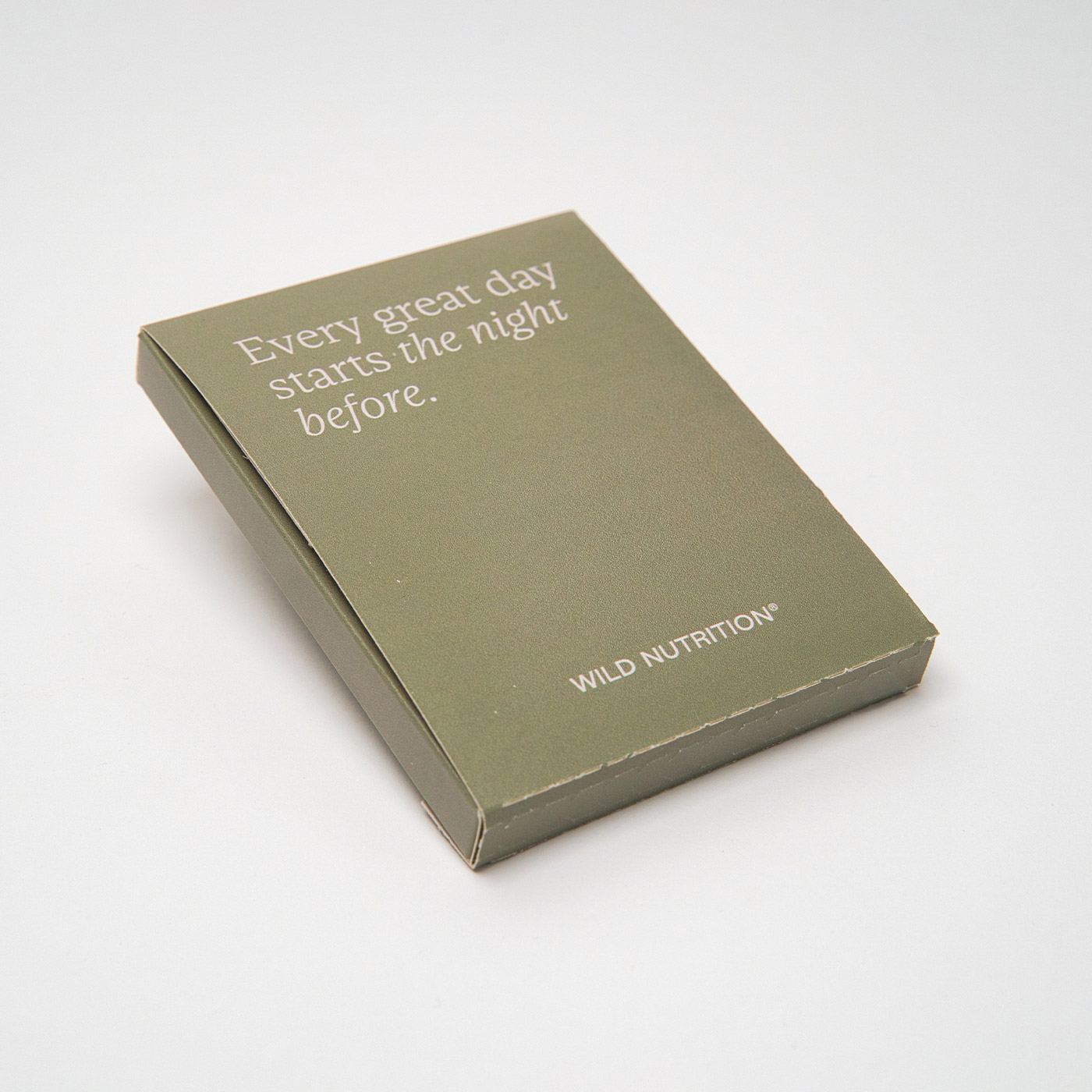

High-value products of excellence such as luxury watches and jewellery, fashion and footwear, fragrances and cosmetics, and wines and spirits.

British businesses producing quality goods across a variety of sectors including personal care items, supplements, chemicals, and pet food.

Be inspired by some of our clients’ bespoke packaging solutions.

Guidance on how to go bespoke, pros and cons of a tailored approach, and plenty of custom packaging hints and tips.

Jul 24, 2023

8 minute read

Oct 11, 2022

9 minute read

Aug 30, 2022

8 minute read

Copyright © 2024 Actionpoint Ltd

PET (1) and HDPE (2) are widely accepted in household recycling waste. Soft/flexible LDPE (4) products like carrier bags can be taken to supermarkets. Remember that recycling facilities differ between councils, so check with your local authority to see what you can put in your home recycling bin.

PP. Polypropylene e.g. bottle caps, margarine tubs, carrier bags.

PS. Polystyrene e.g. takeaway cups and containers, yoghurt pots.